Dao Zhang et al. published a paper on 3D printing high-efficiency color converters for high-power pc-WLEDs in Nature Commun

Recently, Dao Zhang, a graduate student of the College of Optical Science and Engineering, published a paper in Nature Communications with Dr. Wenge Xiao and Professor Jianrong Qiu. They developed a 3D printing and pressureless sintering method to quickly manufacture color converters with high quantum efficiency and excellent physicochemical properties. It is the first time that additive manufacturing of all-inorganic color converters has been achieved, which shows great potential for high-power LEDs and laser lighting.

As a mainstream solid-state lighting technology, white LEDs are widely used in automotive lighting, backlight display, medical and industrial fields due to their advantages, such as high efficiency, small size and long life. However, due to the poor physicochemical stability and low thermal conductivity of organic materials, the traditional "phosphor powder + resin" type color converters will be ageing during high-power lighting based on high-power blue LED or laser diode (LD). An effective method to solve this problem is to use all-inorganic color converters. The "phosphor powder + glass/ceramic" composite has the advantages of high quantum efficiency of phosphor and physicochemical stability of the glass/ceramic composite. In addition, compared with transparent ceramics or single crystals, it has obvious advantages in low cost, mass production, structure/performance tunability, etc.

Generally, the better the stability of the inorganic material, the higher the sintering temperature required for densification. However, previous studies generally believed that the higher the sintering temperature, the stronger the interface reaction between the inorganic matrix material and the phosphor, resulting in a significant decrease in the quantum efficiency of the phosphor.

Usually, one of the traditional solutions is to use low-melting glass or ceramics as the substrate, and the other is to use high-pressure sintering techniques such as gas pressure sintering, hot isostatic sintering, and spark plasma sintering etc. to reduce the interface reaction.

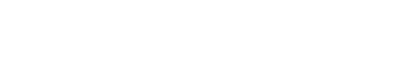

However, the research team found that although the melting point of silica glass is much higher than that of multi-component low-melting glass, the reaction between silica and phosphor (such as YAG:Ce) is suppressed in a small area even when sintering at 1250 ℃ ( As shown in Figure 1), while the reaction between low-melting glass and phosphor occurs obviously at 800℃.

Figure 1. Microstructure characterization at the interface between YAG: Ce particles and silica glass matrix

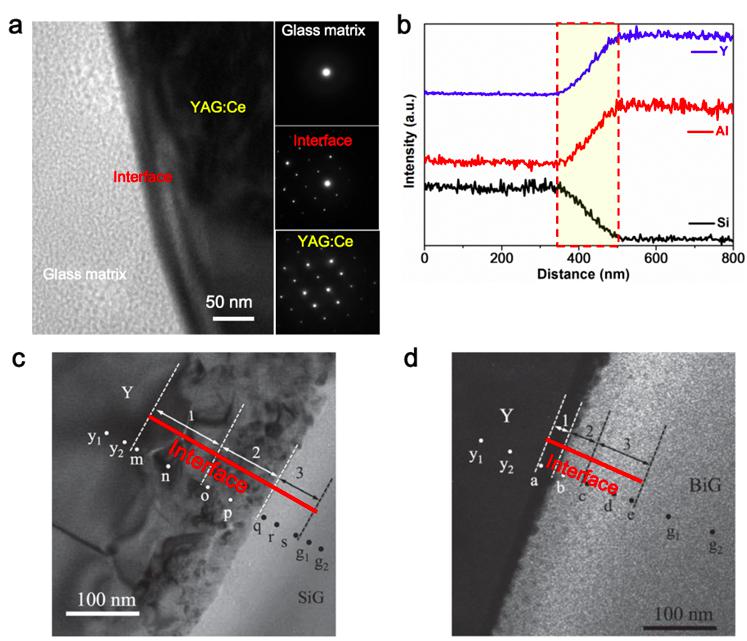

First, they prepared a photocurable "amorphous nano silica + phosphor" slurry. After the composite slurry is light-cured, degreased and sintered, a color conversion device with a quantum efficiency of up to 95% can be obtained (Figure 2). The color converters have high thermal conductivity and excellent physicochemical properties. Besides, the color converters can not only withstand 1200℃ high temperature and 200℃ hydrothermal treatment, but also withstand 455 W laser irradiations of up to 346 W/cm2, showing great potential in the field of high-power LED or LD lighting.

Figure 2. Color converters with high quantum efficiency

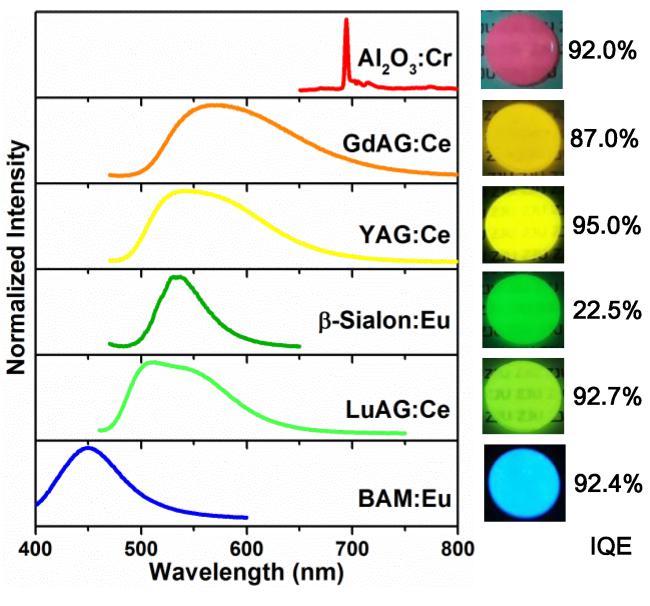

In addition, the traditional technology is difficult to achieve mass production of color converters with complex three-dimensional structures, but the three-dimensional structure is very important for achieving high quantum efficiency and highly integrated devices. By adding a suitable photoinitiator to the photocurable slurry, combined with 3D printing technology and pressureless sintering method, they have achieved the modularization and personalized production of all-inorganic color converters.

Figure 3. Schematic diagram of 3D printed color converters

Their work provides a facile and general synthetic strategy to color-tunable bulk composites based on silica glass for various light-emitting and light detecting applications, which also have strong implications for developing innovative glass based composite materials with high temperature stability.

This work was published on June 4, 2020 in Nature Communications entitled "Highly efficient phosphor-glass composites by pressureless sintering". This work was supported by the National Key Research and Development Program and the National Natural Science Foundation of China.